High Level Feature Overview

- 2 & 5 GHz 4x4 WIFI6 Radio

- Modular HW Architecture

- Modern Lower Profile ID

- Multi-Color LED

- USB-C Console Port

- New Mounting Bracket

- PoE+ / 802.3at (Required) & DC Jack

Mechanical - Case Design

- Custom 2-Piece Clamshell Design made of Poly Carbonate-ABS Plastic

- UL 94V-0 Flame Resistant Plastic, meets UL 62368-1, CSA C22.2, EN62368-1 (EU)

- High (85°C) RTI (Relative Thermal Index) maintains durability in heat and aging. *NOT Plenum Rated for smoke in air handling spaces above ceiling.

- Fully Tested for Temperature, Humidity, Vibration, Mechanical Shock and Drop Tests

- Safety Tested and Rated including RoHS and REACH (EU)

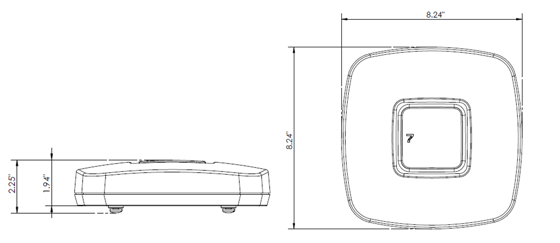

- Dimensions

- 8.24" Square, Outside

- 2.25" High, Including Feet

- Weight

- 1.3 lb. (0.59 kg)

- 1.3 lb. (0.59 kg)

Mechanical - Environmental

- Operating Temperature: 32F ~ +113F (0C ~ +45C)

- Storage temperature: -40F ~ +185F (-40C ~ +85C)

- Humidity: 95% Non-Condensing

- Environment: IP44, indoor usage

Mechanical - Mounting

See detailed instructions here.

Mechanical - Labeling

- PCBA – SN Label - Unit – SN – MAC Label - FCC Label – 3 test labels

- SE6200 – SN on the PCBA and the unit are numerically the same. *

- Added a Version ID on the unit SN label for customer facing changes.*

- Label Placement Flow

- SN/MAC ID labels are preprinted/kitted as part of the Manufacturing shop order. Before SMT starts the labels are affixed to the (raw) PCB (for

SMT). - After SMT/hand solder the SN/MAC labels are scanned and the data is programmed to the EEPROM/Flash (through the test harness code).* T2’s

(test pass label) are applied to the PCBA. - The PCBA then moves to the Box Build where the first step is that the assembler matches the SN/MAC labels on the SE6200 unit to the PCBA SN

(verified). Manufacturing completes final electrical assembly, then the unit goes to upper level (RF) test. Test scans the unit label and compares it

to SN/MAC programmed in the EEPROM (Pass). - When the SE6200 unit passes upper-level test, a T2 (test pass label) is applied to the unit SN Label.

- SN/MAC ID labels are preprinted/kitted as part of the Manufacturing shop order. Before SMT starts the labels are affixed to the (raw) PCB (for

Electrical / RF

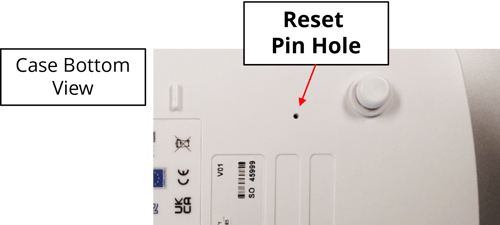

Reset button location and functionality- Primary reset function done by powering down and powering back up

- Reset button available through paper clip hole on bottom, or inside, on board top side

- Reset Button has 3 functions:

- Press and release pin-hole button: Software Reboot, stays powered

- Press for 10 seconds: Hardware Reset, internal peripheral circuits power cycle

- Press for 30 seconds: Forces reload of factory settings

- External Peripherals: 12VDC, 2.0A Wall Adapter from 100VAC ~ 240VAC

- Common, Available Online. Same as used on the 2200

- Manufacturer: Shenzhen Yinghui Yuan Electronics Co., Ltd.

- Model YHY-12002000

- Interchangeable pins for North America, EU, UK

- Standard Barrel connector 5.5mm/2.1mm pin

- Operating Temperature: -20°C to +40°C at 24W Load

- External Peripherals: Power Over Ethernet Injector (PoE+)

- Same as used with the 2200

- Microsemi PoE Injector PD-9001GR

- Outdoor version: PD-9001GO

- Surge Protector version: PD-9001SP

- Operating Temperature: -20°C to +55°C @ 22W

Software - LED Status

| State | LED Status |

| Power off | off |

| Active, but no connection | Blue 2s, Red 2s |

| Active and connected | Blue 2s, off 2s |

| Active and executing tests | Blue |

| Boot failure | Red |